for grain storage

equipment

Grain transportation equipment

Main features: designed to withstand the most adverse conditions in the processing and transportation of grain. Their sturdy and reliable construction guarantees long-lasting use. Made of galvanized steel S350GD with Z - 600 metal coating, the industrial elevator functions effectively with various types of grain, seeds, pulses and pellets.

The dimensions are calculated to ensure the required capacity of the chain conveyor.

Simple mechanical design, high quality of all components and the necessary measure of chain mobility ensure high reliability of the conveyor. The bottom of the conveyor is lined with polytetrafluoroethylene.

Among the main features should be the best combination between conveyor capacity and power consumption ability to transport fragile materials, and materials that disintegrate, reduced noise level during operation. Reliability of operation is ensured by the simplicity of design and quality of elements. Both closed and open carriage conveyors are available.

Designed in accordance with the required capacity. When calculating, we use a fill preservation factor of 45% and do not put too high values, which can give an idea of the throughput features of the equipment. Galvanizing steel sheets (450gr/m2) provides resistance to the effects of the external environment. It is possible to use a synthetic enamel coating.

For ports, transshipment elevators, oil extraction complexes designed for 20 or more turns per year. Capacity ranges from 400 to 2,000 t/year.

Ship-loading equipment is designed based on the customer's current needs and space limitations. All proposed equipment can be seen live at existing facilities.

For ports, transshipment elevators, oil extraction complexes, designed for 20 or more revolutions per year. Capacity ranges from 400 to 2000 t/h. Bucket elevator and conveyors are made to run 24 hours / day 340-350 days per year, in aggressive environment and abrasive material, cargo. All proposed equipment can be seen live at existing facilities.

Equipment for grain storage

For storage of all kinds of grain and seeds. Consists of a cylindrical part and a roof resting on a foundation. Prices for storage and processing of grain, such as elevators, feed mills, vegetable oil plants, mills.

Silos made of galvanized steel S350GD with high tensile strength with Z600 coating, which corresponds to a zinc content of 600 g/m2.

Designed both for long-term storage of grain and for short-term storage before and after technological operations such as drying or cleaning. Silos made of galvanized steel S350GD with high tensile strength with Z600 coating, which corresponds to a zinc content of at least 600 g/m2. Silos are available with 45o and 60o bottoms for different types of products.

Designed for accumulation of raw materials in a silo and its shipment to road and rail transport, tractor carts. Design and production of structures for bulk loading from 20 to 300 tons. They are made of high-strength Z600.

The silo includes the following systems: active ventilation system, thermometry, galleries and supports, automation, unloading, filling level.

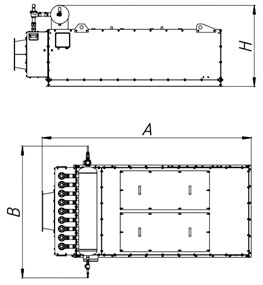

The warehouse is designed for bulk storage of bulk cargoes. The structure of the warehouse includes upper and lower passage galleries, which are equipped with transporters for loading and unloading of the warehouse, respectively. The main advantages are: low cost per ton of storage; high speed of construction, capacity up to 118 569 m3 (up to 143 563 m3 a train on the flat bottom).

Equipment for grain drying and cleaning

It is used for drying grain and seeds of cereals, legumes, corn and cereal crops in agriculture.

The dryer is used as part of the grain cleaning and drying line, additionally contains mechanisms for receiving, transporting and pre-cleaning of grain. Dryers are made with fuel units operating on gas, liquid or solid fuel.

The sieve separator is designed for cleaning and separation of granular dry, bulk materials on a system of sieves, and with the help of air flow in the aspiration cabinet with recirculation, dust and light volatile domestics are removed from the material.

Drum separator for pre-cleaning of granular dry materials before final cleaning.

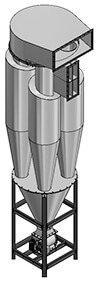

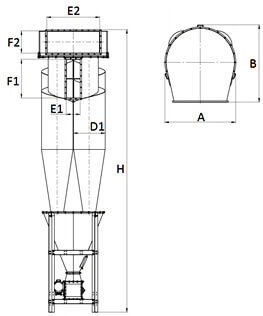

Aspiration equipment

70-80% cleaning efficiency of dusty air;

No costs for preparation and supply of compressed air;

Possible to use for explosive dusts;

Can be installed both indoors and outdoors;

Long service life due to rugged and reliable design;

Easy and convenient installation and maintenance;

Use at low initial dust concentrations to ensure regulatory emissions (less than 50 mg/m3).

ББЦ-200

1030-1170

150

800

ББЦ-225

1430-1610

175

800

ББЦ-250

1760-1980

195

800

ББЦ-275

2130-2460

217,5

800

ББЦ-300

2530-2840

252,5

800

ББЦ-350

3250-3700

265

800

ББЦ-400

4350-4930

312,5

800

ББЦ-450

5650-6350

372,5

800

ББЦ-500

6950-7800

402,5

800

ББЦ-550

8310-9550

492,5

800

ББЦ-200

610

660

2300

200

90

240

212

120

ББЦ-225

620

640

2750

225

100

270

237

140

ББЦ-250

710

735

2900

250

110

300

262

160

ББЦ-275

755

750

3050

275

120

330

287

180

ББЦ-300

790

820

3190

300

130

360

312

200

ББЦ-350

890

915

3570

350

150

420

362

250

ББЦ-400

1020

1045

3900

400

170

470

412

300

ББЦ-450

1090

1115

4255

450

194

534

462

320

ББЦ-500

1190

1215

4585

500

214

594

512

350

ББЦ-550

1290

1315

4925

550

234

664

562

380

Degree of dusty air purification - up to 99%.

Use of sleeves made of highly efficient filter fabrics of European manufacturers.

Camozzi, Mecair regeneration system.

Camozzi automatic controls.

Optimal consumption of compressed air by filters thanks to a patented regeneration system.

Pre-filtering units fitted with self-supporting service platforms.

Ability to design the equipment to operate in ATEX 21 and ATEX 22 areas.

kg

onsumption

PA

etion

JC-1520

1000-

3200

14

400

160

1200

Pulse /

Mechanical

JC-3224

4000-

8000

33

900

180

1200

Pulse /

Mechanical

JC-5225

7500-

12500

52,8

1150

220

1200

Pulse /

Mechanical

JC-5230

9000-

15000

63,4

1200

260

1200

Pulse /

Mechanical

JC-8830

18000-

25000

107,2

2000

300

1600

Pulse /

Mechanical

JC-10932

25000-

34000

142,4

2500

320

1800

Pulse /

Mechanical

JC-1520

155

345

195

150

3010

960

230

JC-3224

200

450

495

195

3915

1250

300

JC-5225

300

600

660

350

4300

1700

300

JC-5230

300

600

660

350

4820

1700

300

JC-8830

400

850

850

450

5600

2900

300

JC-10932

470

980

1100

470

6100

3260

300

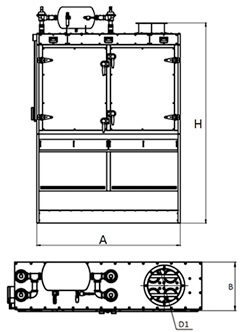

Air purification ~ up to 99%.

Can be installed on any type of receiving hopper.

Increased efficiency of regeneration by optimally selected geometric parameters of nozzles and filtering elements.

Ease of assembly and installation due to parts manufacturing on high-precision equipment.

Operation at temperatures from -30 to +60.

Ability to produce equipment for operating conditions in the ATEX 21 and ATEX 22 zone.

Housing is powder-coated or galvanized steel.

kg

onsumption

PA

JW-20

5000

20

540

320

1200

JW-40

10000

40

1050

320

1200

JW-20

2075

500

3035

355

JW-40

4000

500

3035

355

Local filters are designed for cleaning the air from various types of dry, non-sticky dust.

GAL-JLG is suitable for installation in confined spaces due to its compact dimensions.

GAL-JLV is suitable for bucket conveyors and dredges, where space is limited, thanks to its compact overall dimensions.

GAL-JLK local filter - Cassette bag filters. Can be used in both local and centralized aspiration systems.

kg

onsumption

PA

JL-4

600-1000

4

100

160

1200

JL-6

1000-1500

6

120

160

1200

JL-9

1500-2200

9

200

160

1200

JL-12

2200-3000

12

220

160

1200

JL-16

3000-4000

16

240

320

1200

JL-18

4000-4500

18

260

320

1200

JL-20

4500-5000

20

280

320

1200

JL-4

+1492

975

977

JL-6

1992

975

977

JL-9

1992

1185

977

JL-12

2492

1255

977

JL-16

2492

1465

977

JL-18

2492

1570

977

JL-20

2492

1675

977

Let's meet and discuss all the issues!